Table of Contents

4" furnace safety

Updated 05-16-2012 by Landon

See also: the 4" furnace main page for standard operating procedure, and training information.

The 4“ growth system operates utilizing extreme conditions: the furnace reaches extremely high temperatures (>900 °C), the turbo pumps reach extremely low pressures (~μTorr), the growth feedstock gases are stored at high pressures (>1000 PSI), and many of these gases are flammable. The wrong combination of parameters can lead to costly damages or even lethal outcomes. Please be sure that you understand the dangers and risks before attempting to use the growth system.

Note that above the furnace is a large, red emergency stop button which will shut the system down and terminate all gas flows immediately should a dubious situation arise.

Below are a few things to keep in mind.

Gas leaking into furnace

Under the right conditions, combustion (an explosion) may occur inside the quartz tube during standard furnace operation. This would involve a significant amount of oxygen being present during operation, which would likely be due to a leak of atmosphere into the chamber. The RGA should be used to verify that oxygen levels during operation are in the safe zone.

Hydrogen

Hydrogen is commonly used in growth recipes to reduce metal catalyst particles in order to prepare them to catalyze growth. The gas ratio 75:5:20 (hydrogen:oxygen:other) is border-line flammable. Therefore, if there was an air leak in the CVD chamber during H2 flow, the O2 levels would have to reach 5%. To be safe, our highest allowed O2 fraction must be <1%. A reasonable safety target is <0.1% oxygen, and should be easy to achieve.

Methane

Methane (and other carbon containing molecules) are commonly used in growth recipes as a carbon feed-stock gas to provide the growing nanotubes and graphene with carbon atoms. The gas ratio is 17:17:66 (methane:oxygen:other) is border-line flammable. If there was an air leak in a furnace that was flowing methane, the O2 levels would have to reach 17%. Applying a safety level criteria <0.1% oxygen is clearly sufficient.

Gas leaking out of the furnace

The growth system should only be operated with its enclosure completely closed, and with its ventilation system on to aid in removing any gas that might leak from the system. The enclosure and ventilation system will aid preventing a serious accident, however, they are safeguards which should not be relied upon.

- A leak of flammable gas (methane, ethylene, hydrogen, etc.) could result in an explosion. This risk is compounded by the fact that the furnace often operates at temperatures exceeding 800 °C.

- Hydrogen concentrations between 4% and 75% by volume are potentially explosive.

- Methane concentrations between 4% and 17% are potentially explosive.

- A leak of any gas (including inert gases such as argon and nitrogen) could result in the exclusion of oxygen from the room, potentially leading to asphyxiation of any occupants.

Avoiding gas leaks

Precautions should be taken to avoid gas leaks in the first place. A gas leak could be caused in a number of ways:

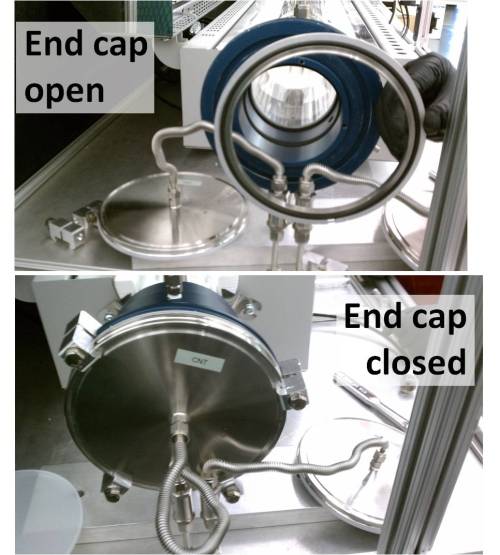

- A leak would occur if the end caps are not closed during operation

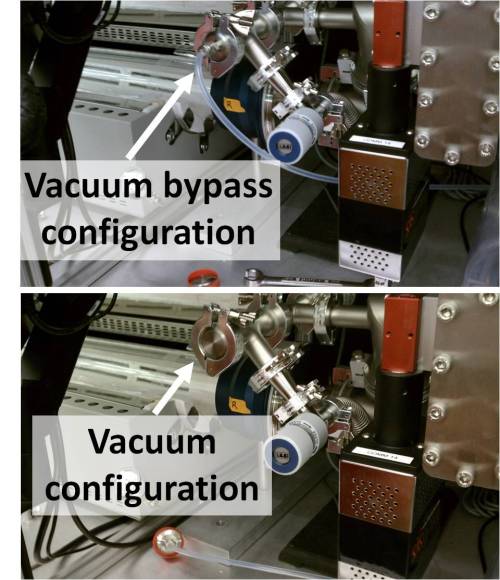

- A leak may occur if a growth recipe is intended to performed at atmospheric pressure, but the vacuum bypass line has not been properly configured. If the system is left in the vacuum configuration then pressure will build inside the quartz tube. Eventually, the quartz tube will shatter (4” growth tubes cost ~$600), or the tube flanges will be blown off. In either case, a large amount of gas will escape into the room.

- A leak may occur if the gas cylinders or their regulators are not hooked up properly.

- Never attempt to use a cylinder with has any sign of damage on it or its regulator.

- Always secure gas cylinders properly to a sturdy object (such as a wall)

Over-pressurizing the quartz tube

The vacuum bypass configuration sends exhaust gas to atmosphere (via the fume hood intake). When the vacuum bypass configuration is in place, pressure inside the chamber will remain at 1 atmosphere. If the the vacuum bypass is not used, and the vacuum pump is turned off, pressure will build up in the quartz pipe. In the worst case scenario, the quartz tube will explode violently. Such explosions are known to embed glass shards into concrete walls.

Turbo pumps

The turbo pumps are sensitive pumps which can routinely reach low pressures (< 1 μTorr). Turbo pumps rely on spinning blades to pump, and these blades can spin as as >10,000 rpm. Conservation of angular momentum tells us that the turbo pump will resist being tilted while in operation, and the turbo pumps will likely be damaged if forced to move while in operation. Most applications of turbo pumps involve them being completely stationary, however our 4“ system is unique in that it is on wheels. Never try to move the system while the turbo pumps are in operation, or while they are spinning down.