Table of Contents

The wirebonder is located in Pallavi Dhagat's lab. Once trained, users need to schedule with Pallavi at least 24 hours in advance before using the wire bonder.

The system is a West Bond 7476E and is set up in wedge bonding mode. As of now (2025) the wire bonder is using aluminum wire to bond.

The wirebonder manual:7476e_manual.pdf

Wedge bonding Theory

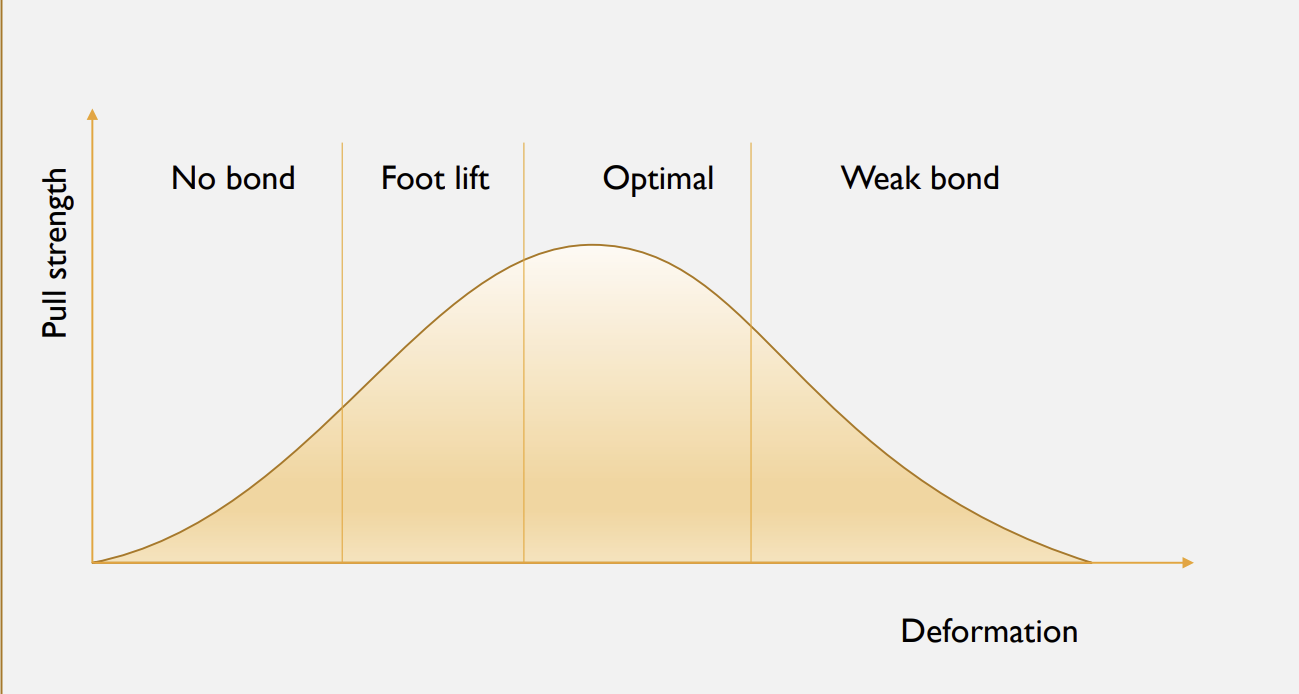

Wedge bonding relies on the application of ultrasonic power and force to bond the wire (bonding wire) to a metal pad (bonding pad). The careful application of both force and ultrasonic power deform the wire and diffuse the wire metal into the pad without weakening the wire too much. The strength of the wire after bonding is shown below as a function of deformation from ultrasonic energy and force applied.

Outside the optimal range,

Foot lift: the bond pulls off the pad, meaning the metals didn't have intimate contact.

Outside the optimal range,

Foot lift: the bond pulls off the pad, meaning the metals didn't have intimate contact.

Weak bond: the wire was deformed too much by the bond tool.

The surface quality is also important. While the deformation needs to be managed, clean and properly adhered bond pads are important to successful bonding.

Threading

There are two key locations the wire must thread through. 1. The shelf 2. The wedge tool

To get the wire through the shelf, you can open the clamps manually.

When properly through the shelf, the wire will not pull out of the clamp when the clamp is open.

To get the wire through the wedge, get a sharp piece of wire by clipping it with two tweezers, and fish through the eyelet. It gets easier with practice.

Making Bonds

Setting sample height: Pull the bond tool all the way to the bottom of its travel and raise the sample so it is almost in contact. Then, raise the stage half a turn. This should allow you to control with just your fingers and wrist.

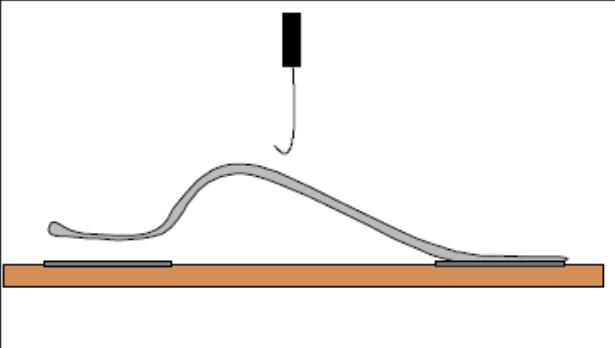

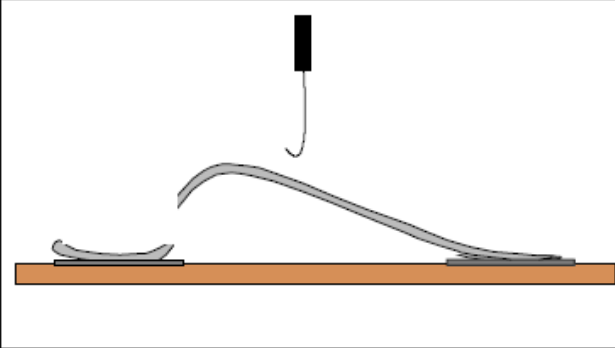

Bonds should be made by moving in straight lines like a helicopter: Touch down briefly to make first bond, raise straight up, move to next bond site, and touch straight down to make second bond. Bonds are always made from the pad closer to you, to the pad farther from you.

Maintenance and calibration

Tuning Deformation With Ultrasonic Energy, and Force

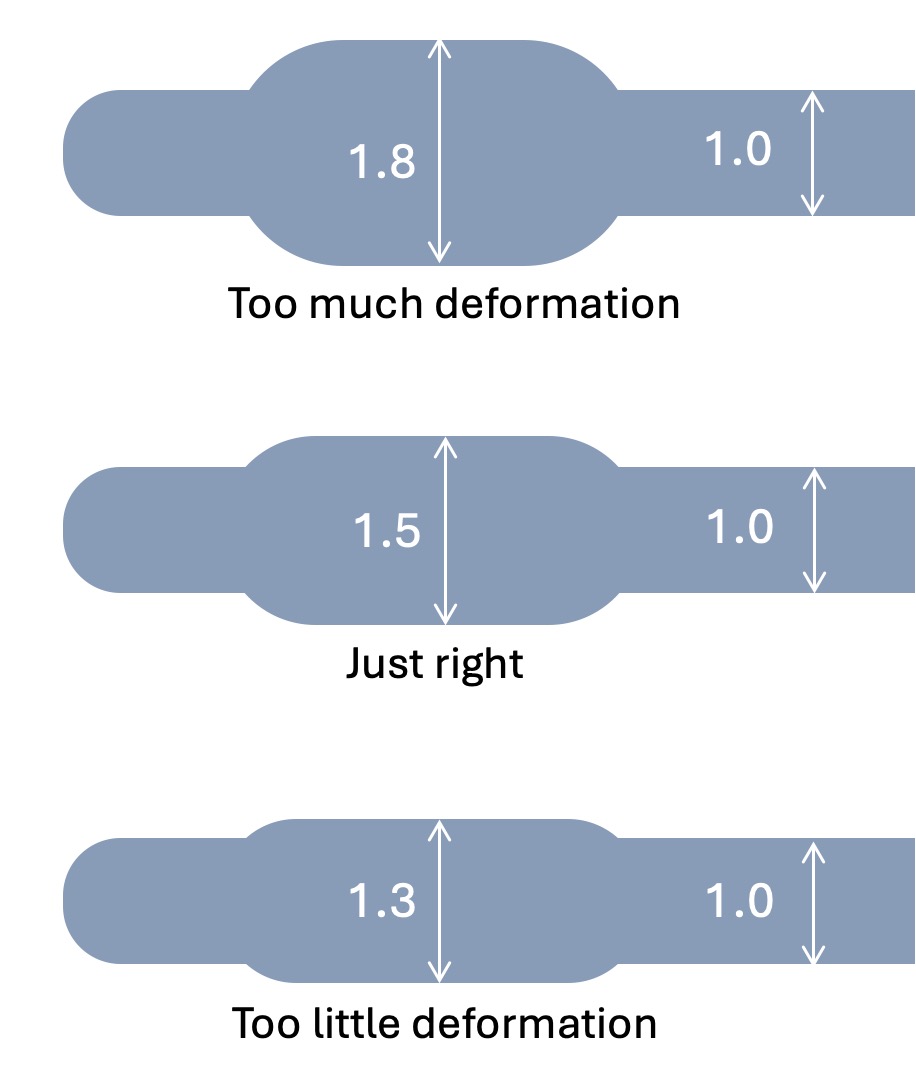

The wire should be deformed aout 150% of the original width. See below:

To tune this, do the following: The force is set by the wire diameter. 25 mil gets 30 g of force as measured by the dynamometer.

Start with a low ultrasonic energy, 150, and increased until the wire bonds consistently. If you get to the maximum, your issues may be related to the surface quality.

Measuring the force

For 25 mil wire, 30 g of force is recommended.

Testing the ultrasonics

There are a handful of electrical tests for the tool. When Matt Ritchie, the engineer from West Bond, was here, he did three. - Test the oscillator frequency - Test the output voltage, V_rms, (See 4.12) - Test the transducer frequency. This one is important as it relates to the life of the tool.

These are on pg. 26 of the manual

Aligning the clamps

Realignment should be done with the tool threaded. The

To change the separation of the clamp and wedge, open the motor settings by holding down edit while powering on. During the site visit, 46 was a good known setting. This relaxes the constraints on how aligned the tool needs to be in order to get good feed of the wire. If this is set too high, the wire will not come in at the right angle.

The wire should come out of the bond tool straight towards you when everything is aligned.

Misc.

- The wedge tools can build up with Al. Used 5% Sodium Hydroxide bath to dissolve the Al, then alcohol clean up.

- Industry standard is to replace Al wire every 12 months.

- The drop before clamp parameter is better left off. When on, when lowering the tool after the first bond, the clamp will engage. This tension can be problematic.

- The loop height parameter only changes when the tool beeps when raising the bond head. It has no mechanical impact on the bond.